Innovation in resins and equipment has become the core driver pushing industry boundaries. Through breakthroughs like functional resin matrices and micron-level precision systems, HeyGears is not only overturning the outdated perception that resin parts are fragile and inefficient but also establishing new paradigms across performance, manufacturing efficiency, accessibility, and sustainability. The following section breaks down five key innovations, explaining how resin 3D printing enables the rapid transition from idea to functional product, and the practical value of HeyGears’ technologies.

The Materials Revolution

The evolution of resin materials is the core driver of 3D printing innovation. HeyGears’ high-performance resin matrix shatters the stereotype that resin parts are brittle and delicate. Their High-Transparency Resin (PAT10), with 88.5% light transmittance rivalling acrylic, resists yellowing for up to 8 years indoors, making it ideal for consumer electronics like headphone shells and transparent models. The Elastic Tool Resin (PAE20, 70A) boasts 320% elongation at break and a tear strength of 40N/mm, allowing direct printing of stressed components like shoe midsoles and bicycle seals without secondary processing. Most groundbreaking is the Soft Finished Product Resin (PAF10), which combines 46% elongation with 52J/m impact resistance, giving delicate items like miniature models and keycaps both refined aesthetics and durability.

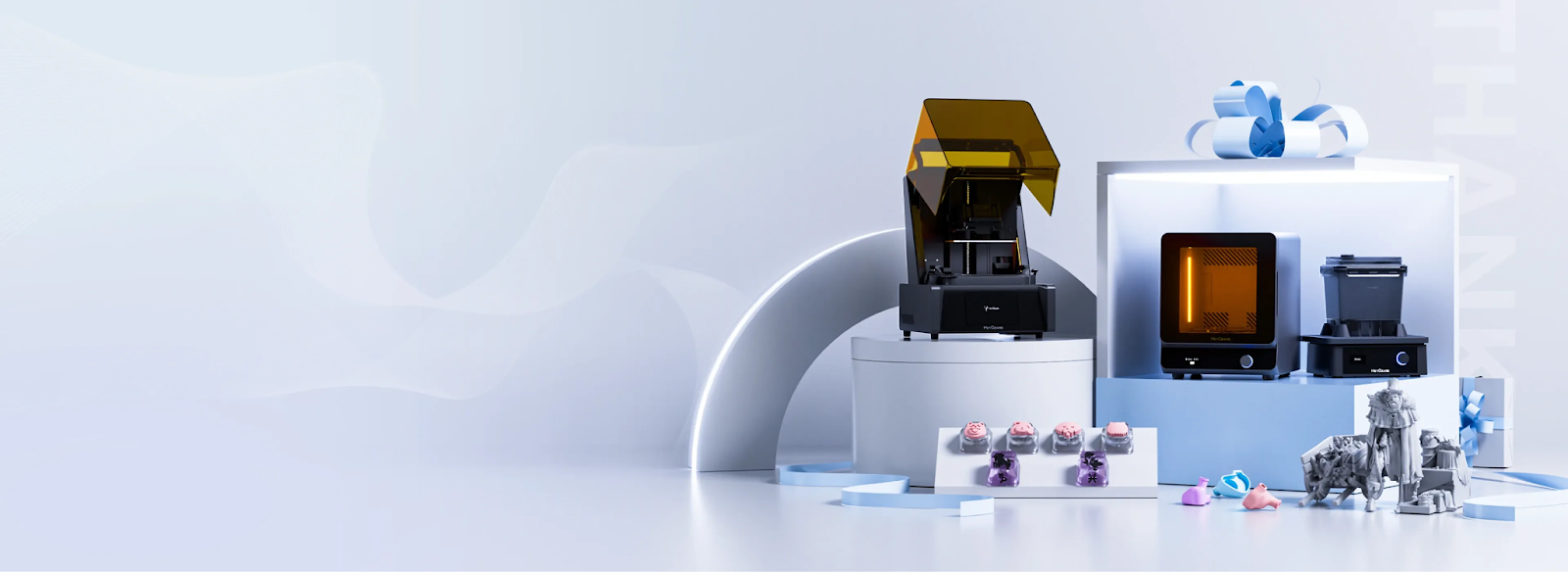

Micron-Level Precision

The HeyGears Reflex series elevates precision to a new level. The Reflex RS features an industrial-grade C5 Z-axis module that maintains a deviation of just ±2μm after 10,000 continuous cycles under a 50kg load. Paired with a full-format, precisely calibrated screen divided into 60 zones, it consistently holds printing tolerances within 0.05mm, making layer lines virtually invisible to the naked eye. This precision enables the reliable printing of complex functional parts, such as consumer electronics housings with tiny snap-fits or home decor pieces with intricate latticework, which can be assembled seamlessly.

Intelligent design further ensures this accuracy. Using 180 Z-axis compensation parameters, the system automatically adjusts printing settings for different edge profiles (straight lines, curves), minimizing deformation and material buildup on support surfaces. For makers, this means printing precision gear prototypes where tooth engagement error is less than 0.1mm, suitable for direct use in small mechanical assemblies. Hobbyists can effortlessly create figurines with rich details like intricate clothing and hair strands, fully capturing the design’s essence.

Rapid Manufacturing System

The traditional bottleneck of slow speed in Resin 3D printing is being shattered by the Dynamic Motion Algorithm 3.0. The Reflex RS employs a 7-segment motion control logic, reading data from its force sensor 80 times per second to seamlessly switch speed gears. Combined with high-speed resins like PAWW10, it achieves an average printing speed of 4.5 seconds per layer for lattice structures. A 561-layer model can be completed in just 71 minutes. Crucially, this speed gain doesn’t sacrifice quality, producing prototypes rivalling injection-moulded parts in just 2 hours and freeing small-batch production from reliance on expensive moulds.

This innovation is already delivering tangible value. For businesses, printing jigs and fixtures on the Reflex RS allows for same-day design verification and testing. Even individual users customizing phone stands or custom earbud tips can enjoy a next-day pickup and, efficient experience.

Full-Process Automation

The democratization of 3D printing hinges on reducing operational complexity. The Reflex series sets a new standard for automation: pre-processing takes about 1 minute, and with one-click slicing, the software automatically repairs model holes and generates supports, enabling even beginners to get started within 15 minutes. The printer is equipped with main spindle and sub-screen force sensors with 0.1N accuracy, capable of detecting debris as small as 0.2mm and automatically halting the print. Combined with post-print analysis reports, this drastically reduces failure rates.

Automation extends to material handling as well. An optional heated resin tray brings materials to their optimal printing temperature within 20 minutes, and the automatic top-up function enables long-duration prints without manual intervention.

Green Manufacturing Innovation

Resin 3D printing is reshaping sustainable manufacturing ideas. HeyGears achieves multiple eco-breakthroughs through technical innovation: the printing process produces no exhaust fumes, on-demand production minimizes material waste, and hollowing techniques further reduce material use and product weight. The materials themselves are also becoming more eco-friendly. For instance, PAF10 resin has a water absorption rate of only 1.6%, resisting cracking over time and extending product lifespan. The underlying technology of water-washable resins hints at a future where more resin parts can be cleaned without harsh solvents, reducing environmental impact.

Practical cases confirm this value. In industrial settings, using high-temperature resistant resins like PAH10 3D printing resin to print master moulds for silicone casting increases reuse cycles by 50% compared to traditional moulds, lowering resource consumption. For eco-conscious users, printing household items and organizers with these resins results in highly personalized products that also align with a low-carbon lifestyle.

Conclusion

When the HeyGears Reflex RS completes the 561st layer of a lattice model, when a keycap made from PAF10 resin survives a hundred drops intact, and when the M-Oktas toy car goes from concept to final product in two weeks through modular design—these specifics signal a pivotal shift of resin 3D printing from a lab technology to a mainstream manufacturing force.

The five innovations detailed above are not just a list of isolated technical specs. The materials revolution breaks the cognitive shackles of unreliable resin parts, giving practical items like headphone shells and jigs the value for mass production. The combination of micron-level precision and high-speed manufacturing liberates small-batch customization from mould dependency, offering SMEs and makers a new production path of validate today, produce tomorrow. Breakthroughs in full-process automation and green manufacturing allow this technology to serve both the factory floor and the home creator, truly achieving low barriers and wide adaptability.

HeyGears’ approach is particularly instructive. Its resin matrix isn’t developed just for top performance specs but is precisely engineered around practical scenarios—PAT10’s yellowing resistance meets the long-term aesthetic needs of consumer electronics, while PAE20’s high elasticity solves load-bearing challenges for sports accessories. The Reflex printer series isn’t merely about stacking precision and speed; it’s about balancing professional-grade quality with mainstream usability through technologies like the C5 Z-axis and dynamic motion algorithm, making 15-minute setup and 0.05mm tolerance achievable simultaneously.

This scenario-centric integration of technology is the core logic enabling resin 3D printing to break out of niche circles. Perhaps the future of 3D printing innovation won’t need to emphasize being astonishing, because its ultimate value is realized when the technology seamlessly integrates into manufacturing chains and daily life, becoming a standard tool that solves production pain points and meets everyday needs. Right now, the comprehensive breakthroughs—from materials and equipment to processes and sustainability—are accelerating the arrival of that future.